One-Step Surface Preparation That Saves Time Across Job Sites

Modern Crews Rethink Surface Preparation

One-step surface preparation helps crews across paving, construction, utilities, aviation, and industrial job sites replace sweeping, reduce cleanup passes, and keep work moving. As schedules tighten, traditional sweeping can add time and extra equipment before the next phase begins.

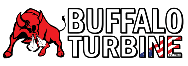

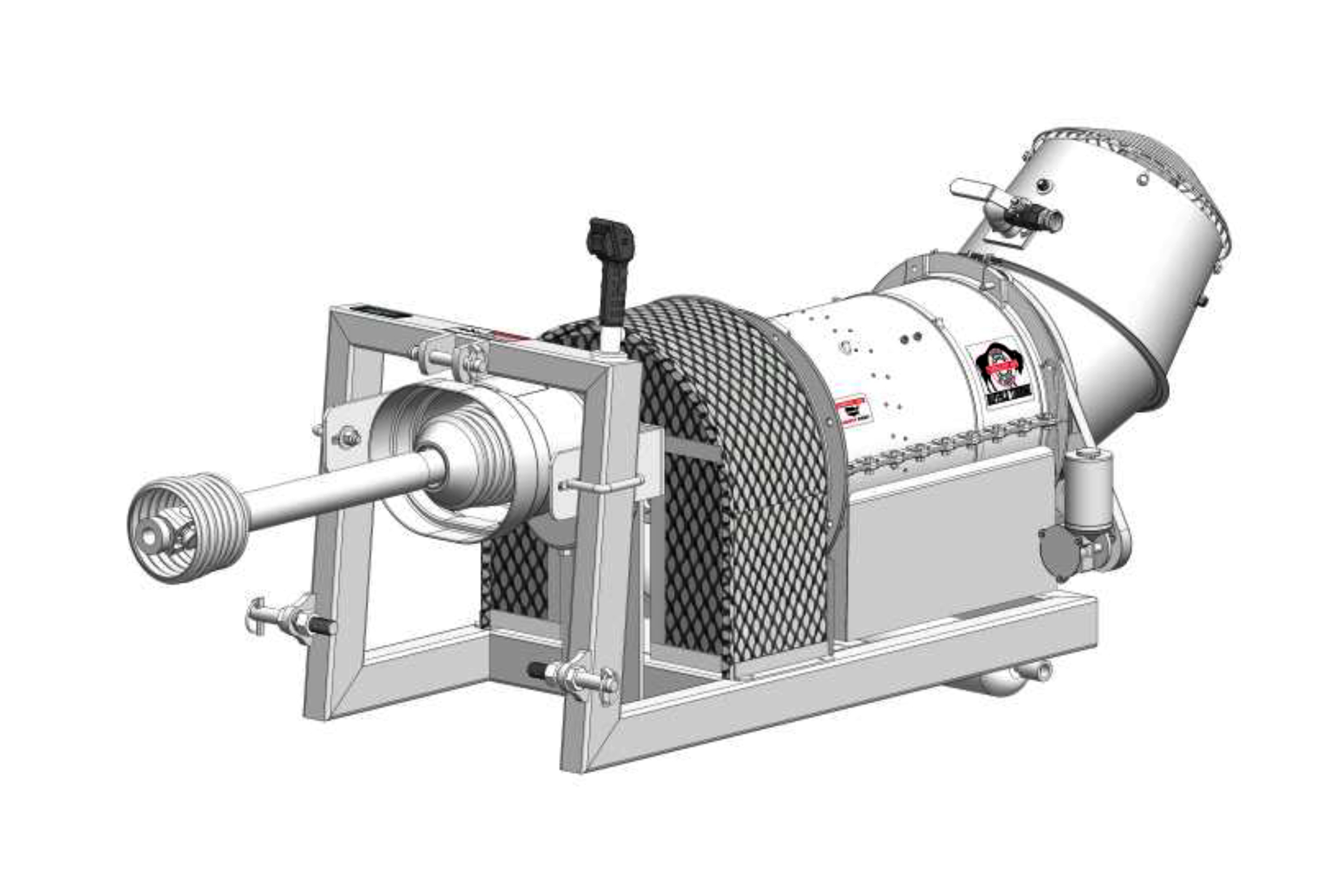

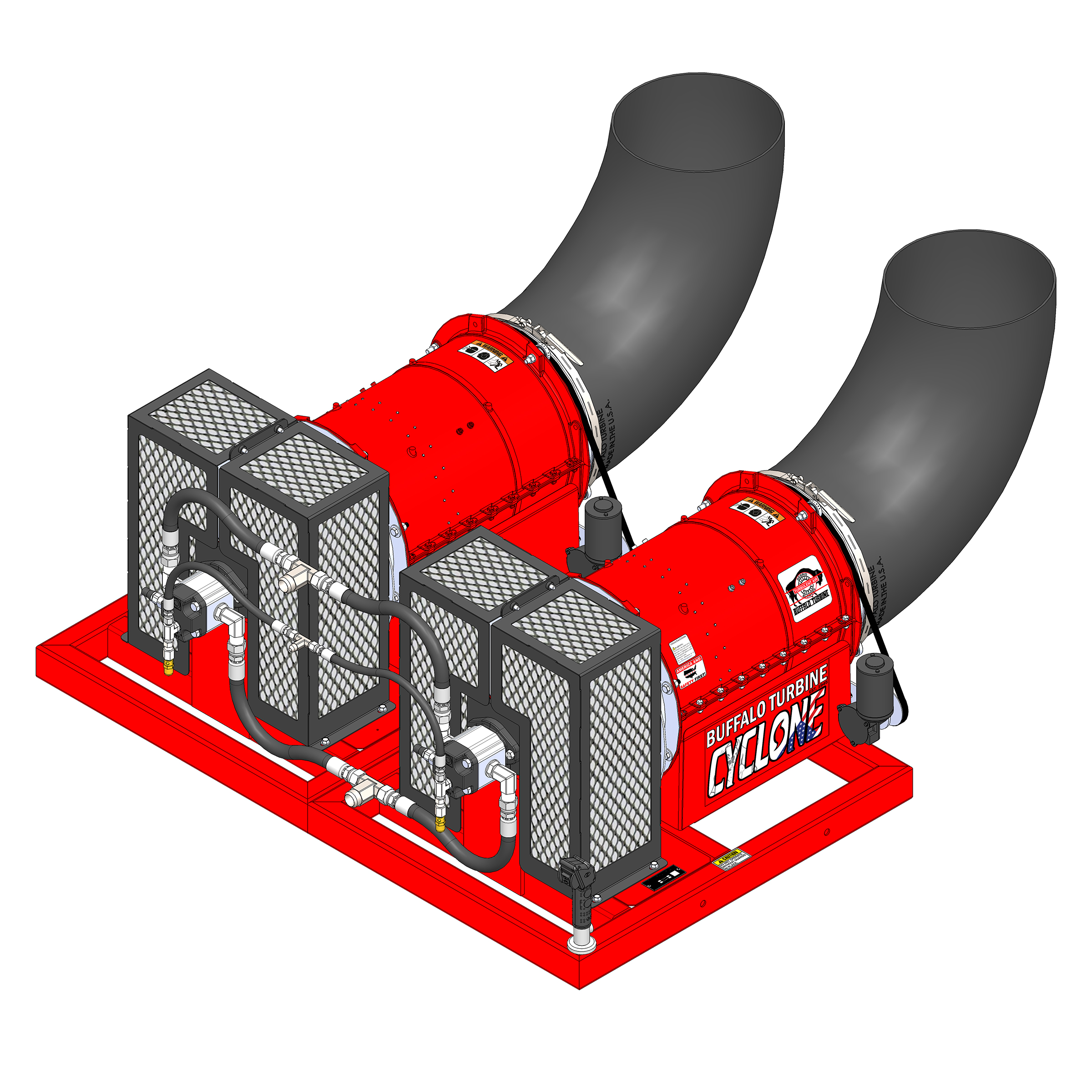

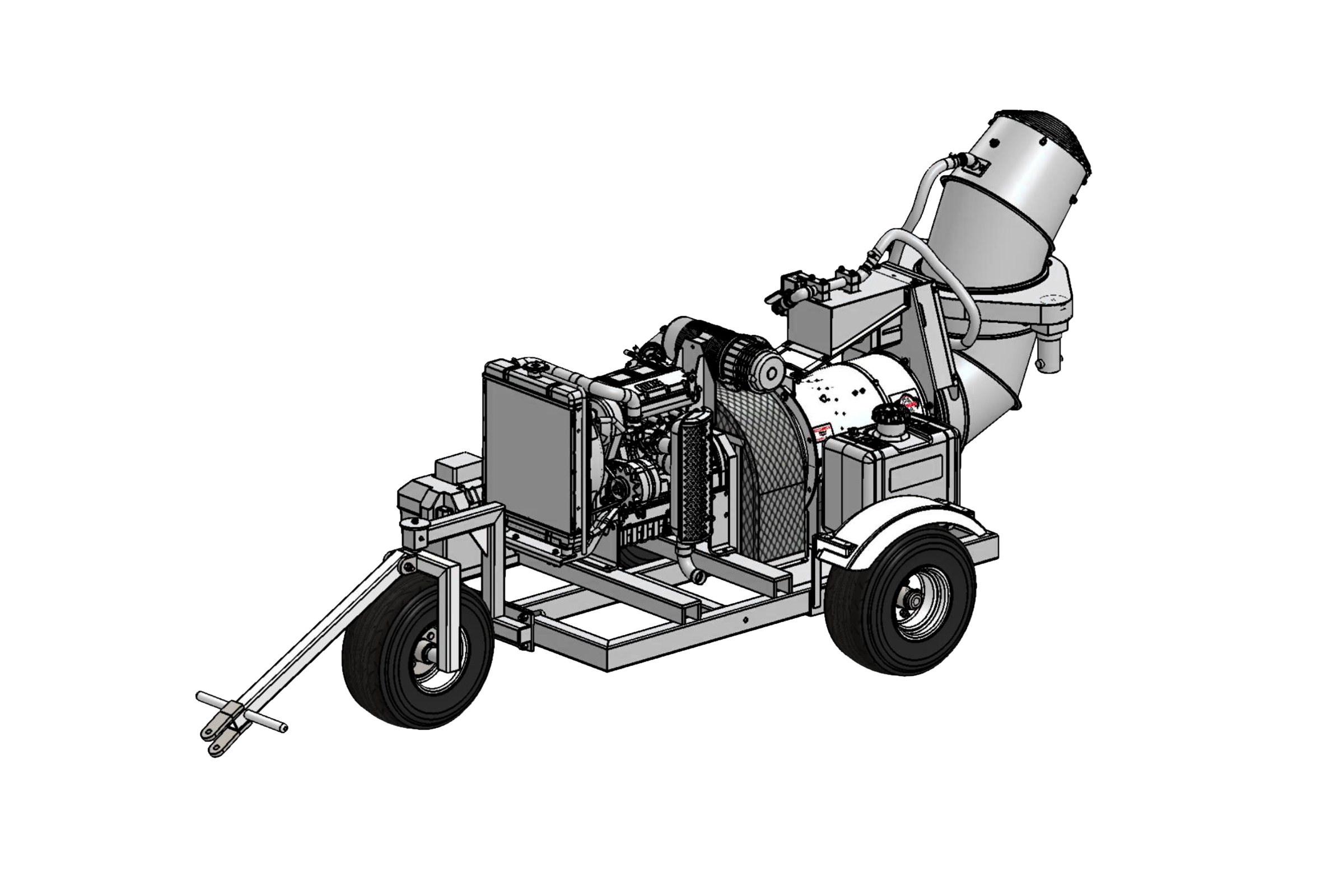

Buffalo Turbine delivers turbine-force air that clears dust, sand, millings, and loose debris in a single pass. As a result, crews transition faster from cleanup into paving, placement, restoration, or production.

One-Step Surface Preparation: What It Means on the Jobsite

In practice, one-step surface preparation means clearing dust, sand, millings, and loose debris efficiently enough to move directly into the next task. Instead of relying on repeated sweeper passes, turbine-force air clears the surface in a single pass, so production stays on schedule.

Why Surface Cleanliness Matters Before Paving and Construction

Surface cleanliness directly affects performance because debris can interfere with bonding and compaction consistency. Over time, that weak interface may contribute to premature cracking, raveling, or delamination. Therefore, debris removal is a performance step, not a formality.

For additional context, review municipal roadway construction guidance (opens in a new tab) and, similarly, standard asphalt paving workflows (opens in a new tab) .

Bonding

First, dust and fines can reduce adhesion between lifts and at joints.

Compaction Consistency

Next, loose material may contribute to inconsistent density and weak spots.

Durability

Ultimately, cleaner surfaces support longer service life and fewer callbacks.

Sweeping vs One-Step Surface Preparation

- Often requires multiple passes

- Meanwhile, residual fine dust can remain at the bond line

- Brush wear and maintenance add operating time

- Consequently, crews spend more time inside lane-closure windows

- Single-pass removal of dust, sand, and loose debris

- Additionally, high-velocity, directed turbine air targets problem areas

- No brushes or belts to adjust or replace

- As a result, crews transition faster from prep to paving or restoration

Beyond Paving: One-Step Surface Preparation Across CONEXPO Industries

One-step surface preparation saves time anywhere clean surfaces and fast transitions matter. For example, Buffalo Turbine supports production across heavy civil and infrastructure, utilities, aviation, industrial facilities, aggregates, and disaster response cleanup. In other words, the same approach scales across job types.

Construction and Infrastructure

- Heavy civil and site preparation

- Utility trenching and backfill cleanup

- Bridge decks and structural surfaces

- Concrete pours requiring clean substrates

Industrial, Aviation, and Aggregates

- Airport runways, taxiways, and aprons

- Aggregate yards and material handling areas

- Industrial facilities and loading zones

- Disaster response and large-scale debris removal

Where Buffalo Turbine Fits at CONEXPO

See One-Step Surface Preparation Across Industries at CONEXPO-CON/AGG 2026

Buffalo Turbine debris blowers are trusted across paving, construction, utilities, aviation, industrial, and municipal job sites where time, surface conditions, and productivity matter. To see how turbine-powered debris removal replaces sweeping, visit us at CONEXPO-CON/AGG 2026 in Las Vegas.

Frequently Asked Questions

Why is debris removal critical before asphalt paving?

Debris such as dust, sand, and loose aggregate interferes with asphalt bonding and compaction. As a result, one-step surface preparation helps support adhesion between layers and long-term pavement durability.

Can Buffalo Turbine debris blowers replace traditional sweepers?

Yes. Buffalo Turbine blowers are designed to replace mechanical sweeping by delivering high-velocity air that removes fine debris in a single pass. Consequently, crews can reduce or eliminate multiple sweeper runs.

How does one-step surface preparation save time on the jobsite?

One-step surface preparation reduces equipment passes, labor requirements, and downtime. In turn, crews can move directly from cleaning to the next phase, which is especially valuable during night work and tight lane-closure schedules.

What types of projects benefit most from turbine-powered debris removal?

Paving and resurfacing, utilities and infrastructure work, airports, industrial facilities, and aggregate operations all benefit from fast, consistent surface cleaning. For that reason, one-step surface preparation is a fit across many CONEXPO job sites.