Buffalo Turbine Introduces Time Saving Nozzle Clamp Band System.

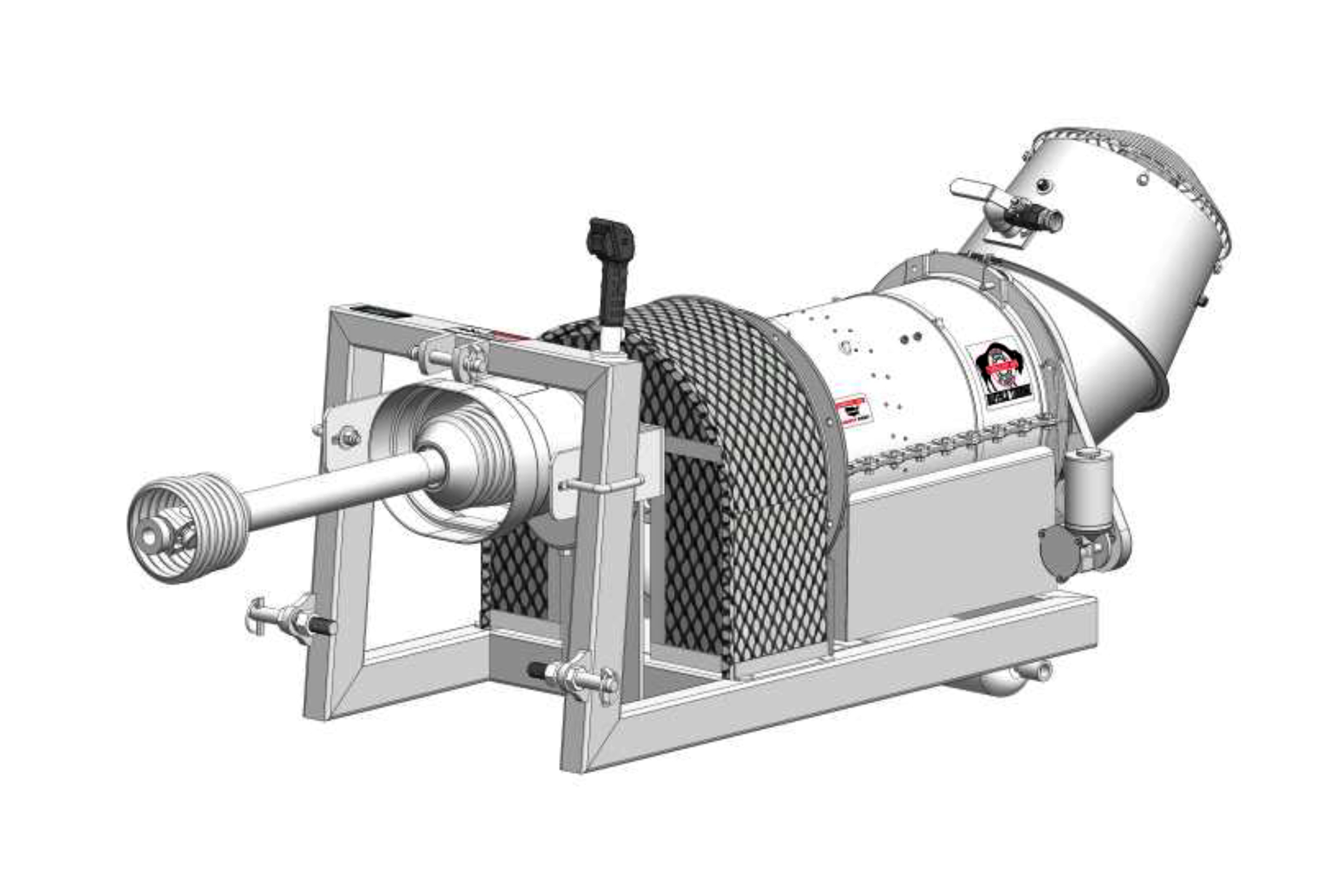

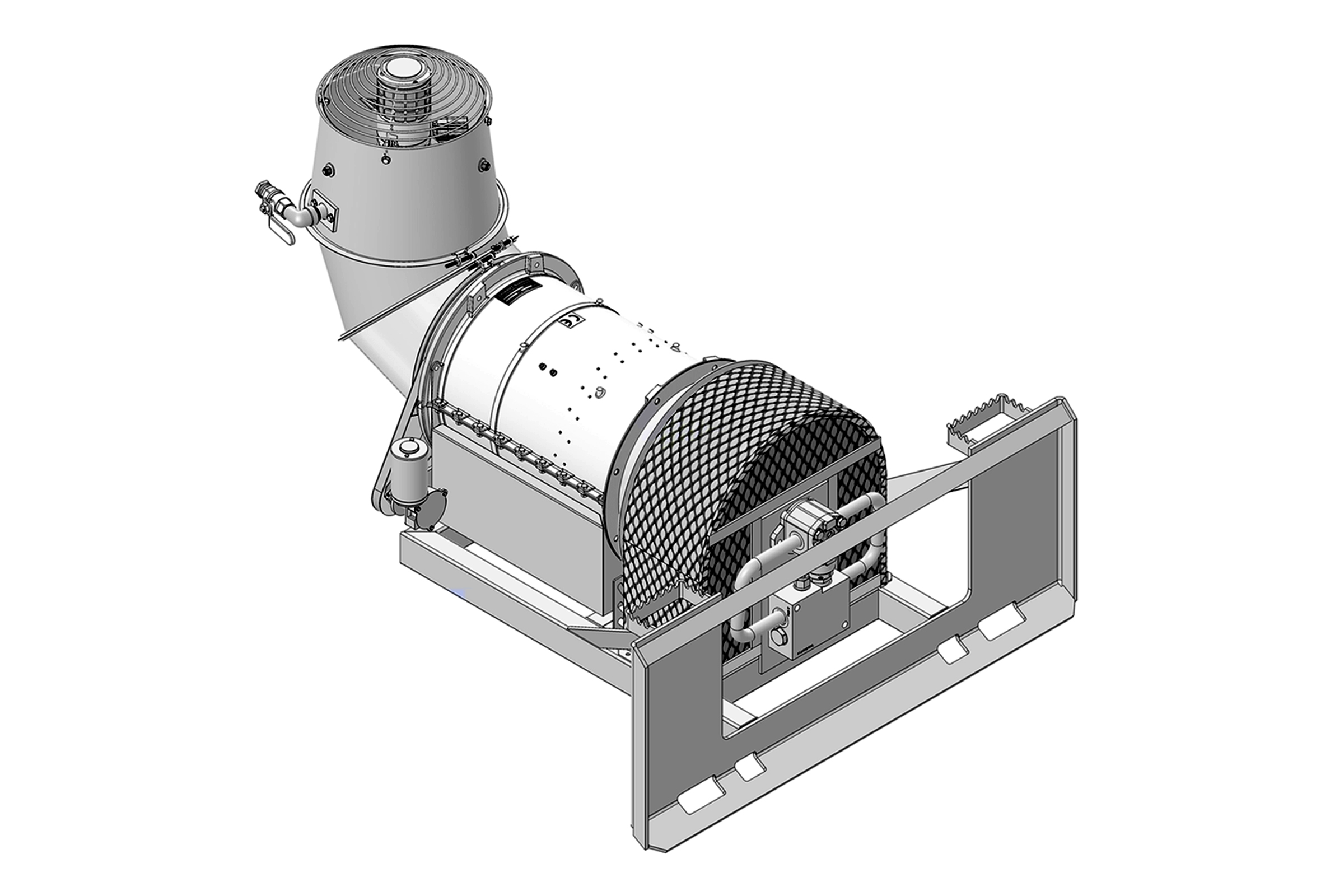

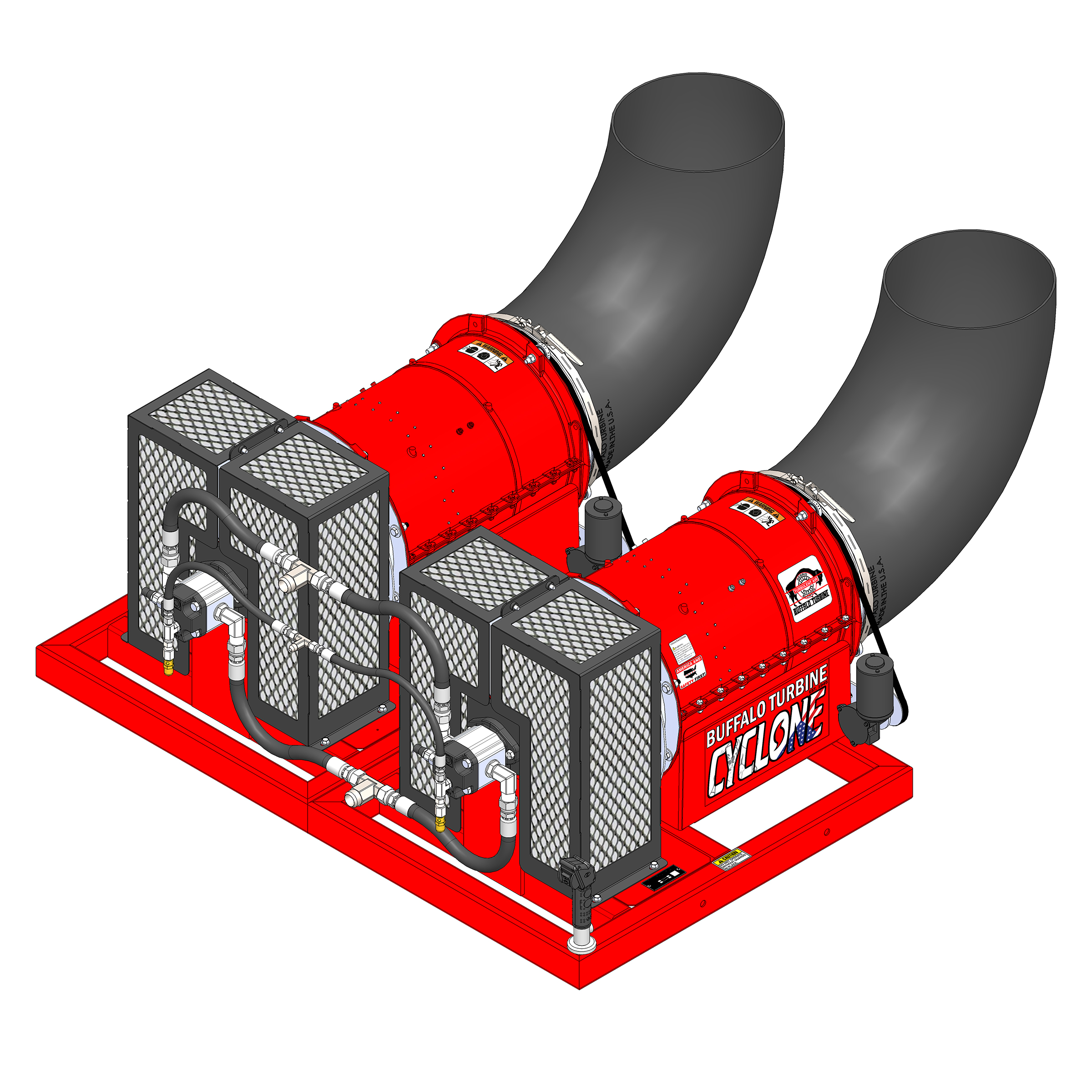

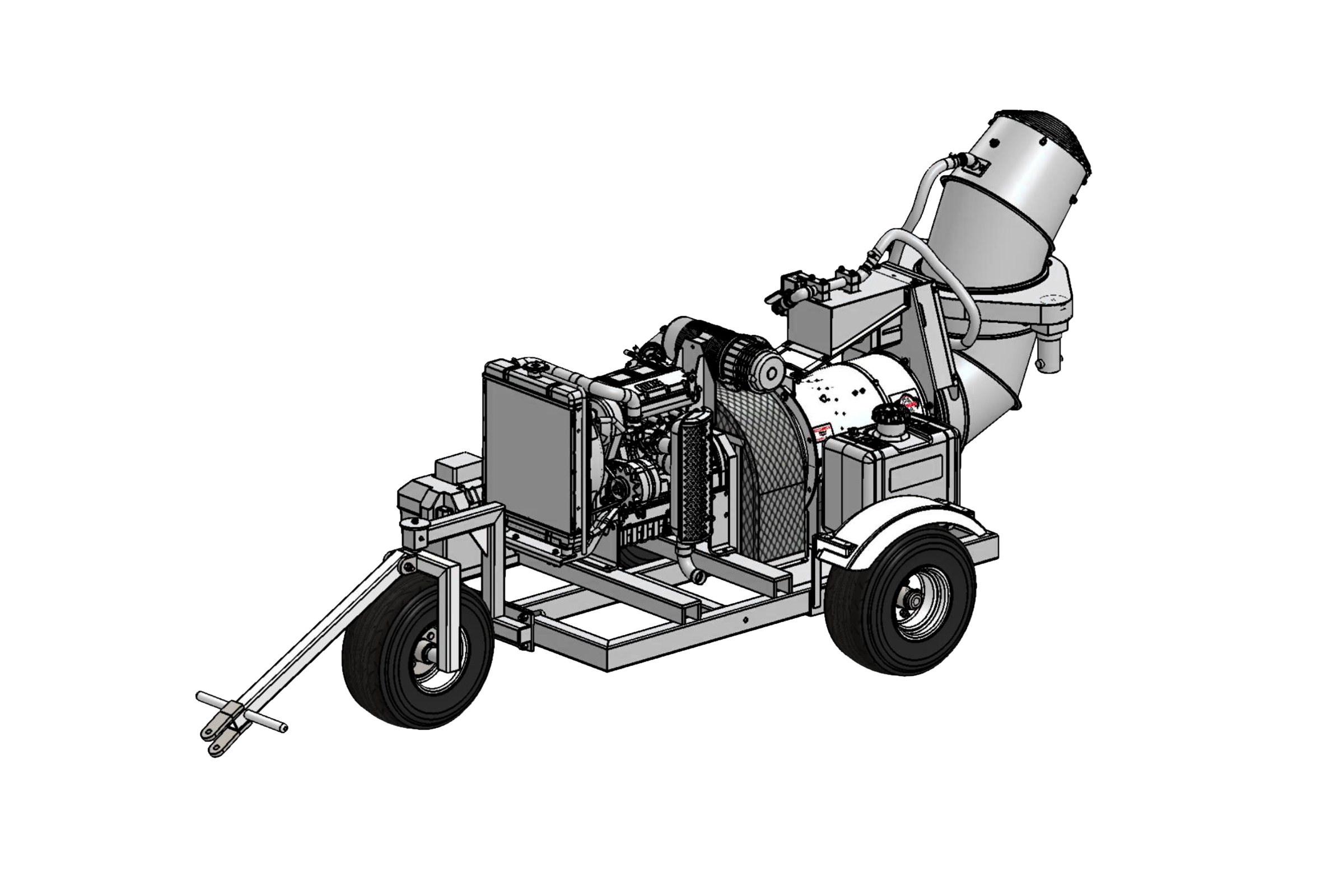

Springville, New York (November 14, 2023) – Buffalo Turbine introduces the new quick release Clamp Band System. Ideal for saving time and effort when transporting your Buffalo Turbine debris blower or using many nozzle options. The system features a quick release latch for easy removal and secure attachment of the turbine nozzle. All Buffalo Turbine debris blowers now ship with the new Clamp Band System as standard equipment. For existing customers, the system can be retrofitted to machines already in the field.

“Buffalo Turbine has always been quick to market with our new innovations. Our dealers and customers asked for a quicker way to attach and remove the turbine nozzle. We are happy to deliver this new Clamp Band System,” said Fran Kuras, Service/Parts Manager Buffalo Turbine. “Buffalo Turbine has been the leader and innovator in turbine blowers since 1945 and will continue to improve the user experience.”

The Clamp Band System, part number 4935 can be ordered through local Buffalo Turbine dealers. For more Information about Buffalo Turbine products visit Buffalo Turbine’s web site at www.buffaloturbine.com.