Buffalo Turbine Honoring Military and Civil Service Personnel This Holiday Season.

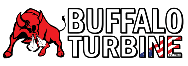

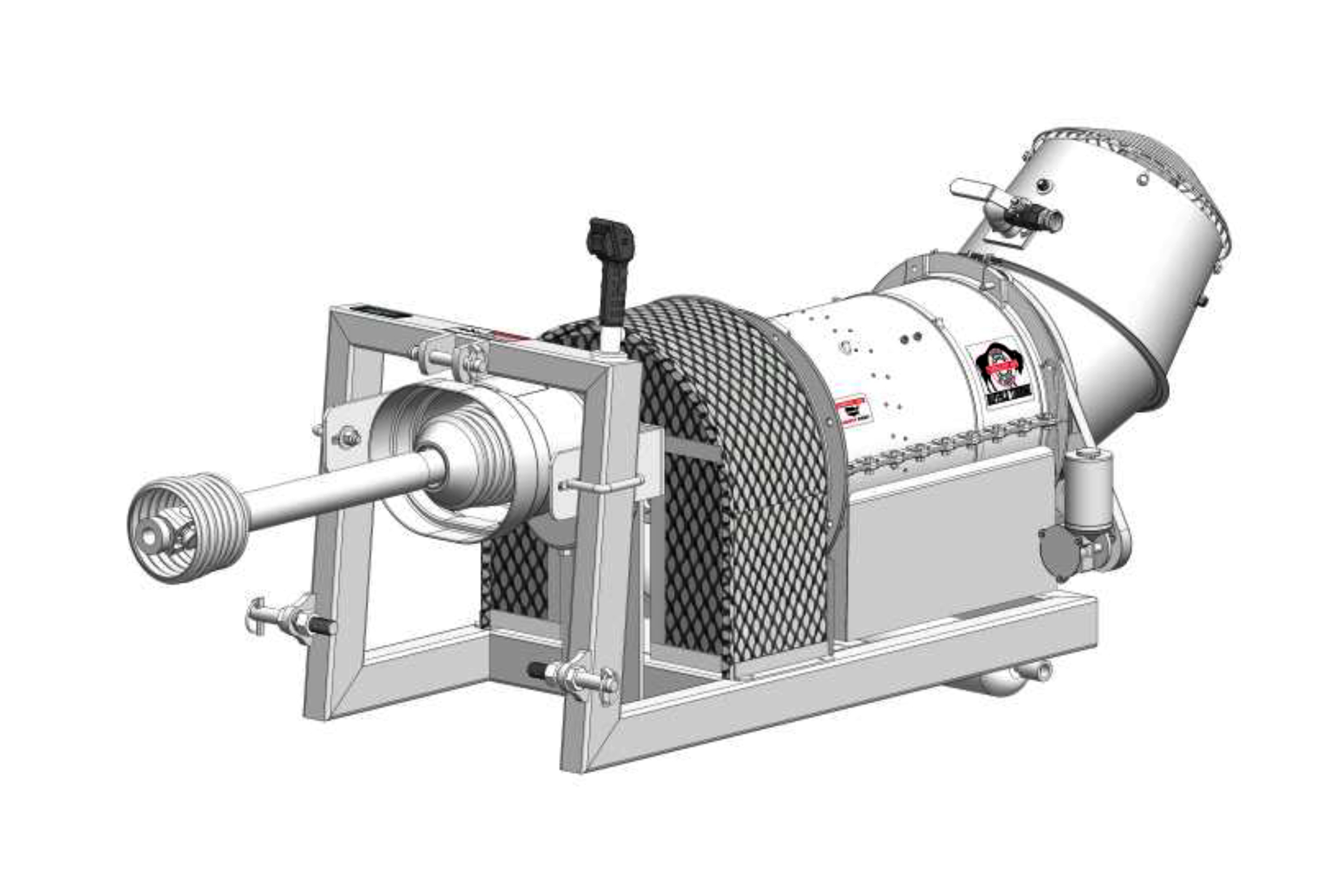

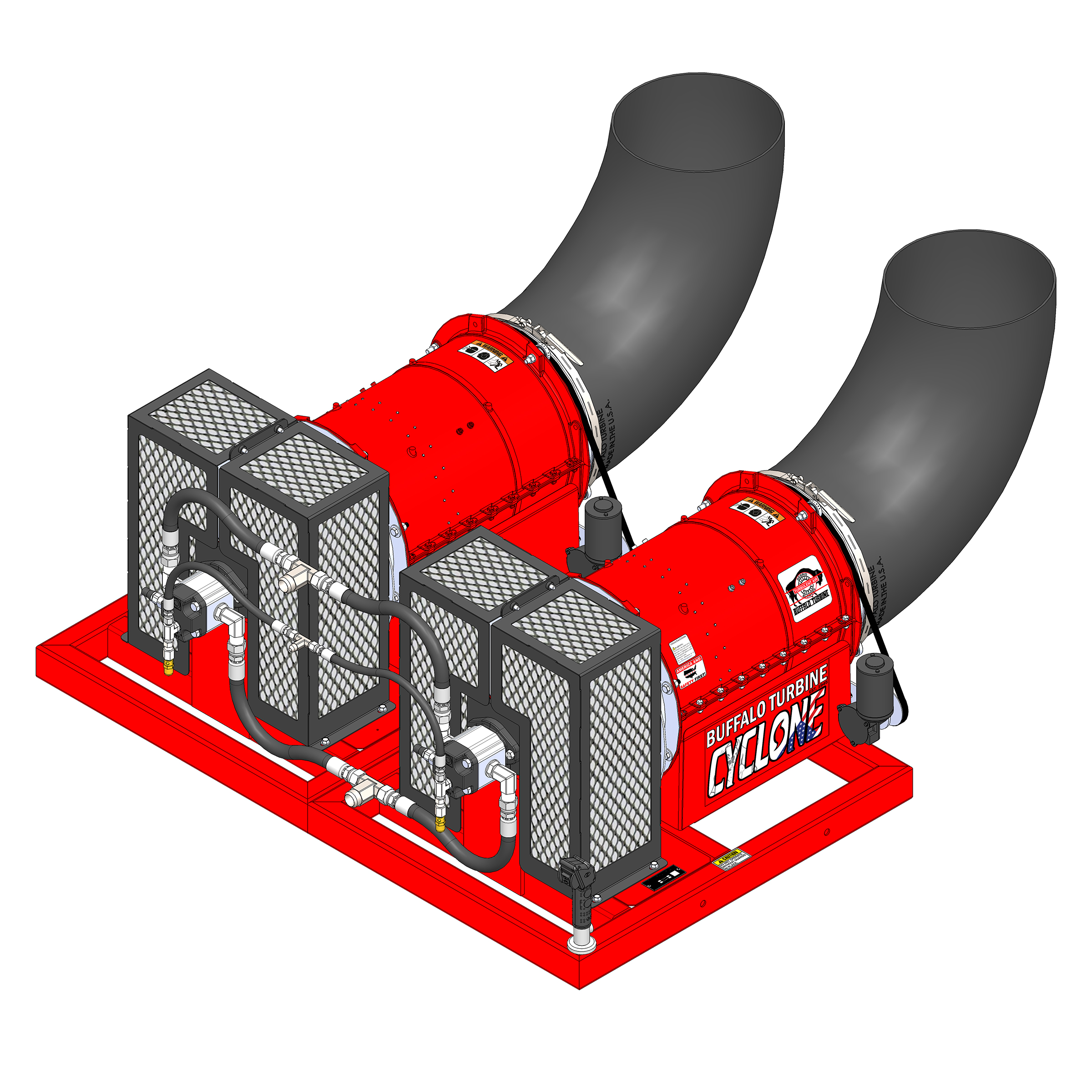

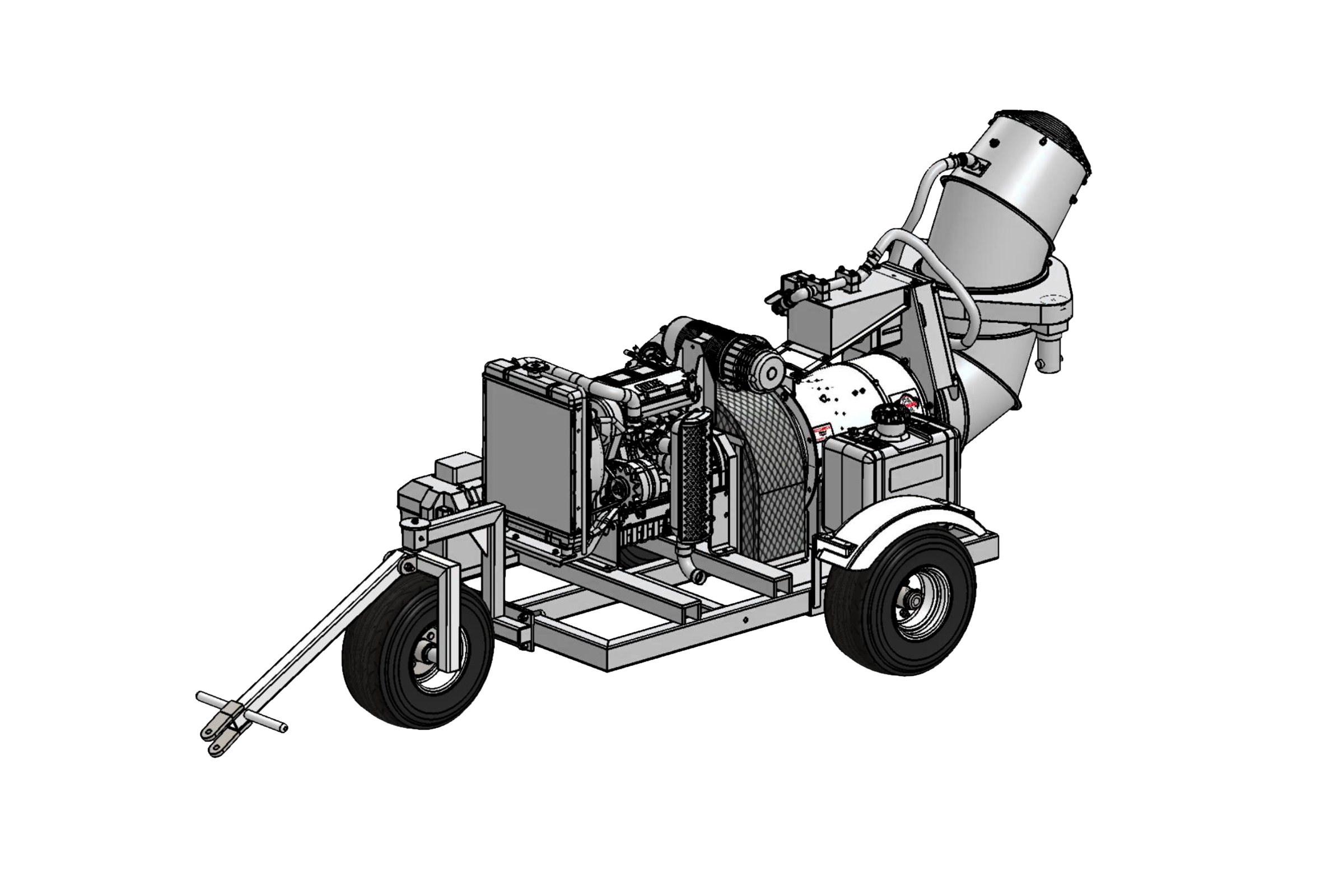

Springville, New York [December 14, 2023] – For over 75 years Buffalo Turbine has supplied our military and municipalities with turbine debris blowers for a variety of applications. The same proven Buffalo Turbine debris removal used on golf courses and racetracks also clears airbase runways, public parks & sports fields, uncovers improvised explosive devices in the field, and helps prevent mosquito carried diseases on base and in municipalities.

Public use of Buffalo Turbine debris blowers date back to the company’s origins in Gowanda, New York. Immediately following WWII, technology and manufacturing advancements allowed for the commercial use of turbulent air to move objects. It quickly proved more efficient and economically viable over manual labor and heavy equipment. It’s lightweight design also reduced rutting and soil erosion in agriculture use.

Today, Buffalo Turbine headquarters and manufacturing remains in nearby Springville, New York “Our military demands precision tolerance and lasting durability in the harshest conditions,” remarks Cheryl Horschel, Vice President of Buffalo Turbine. “Building to military spec, plus ISO 9001 certified quality systems, carries into our entire product line. It’s why Buffalo Turbine debris blowers come with a 10 year warranty.”

For more Information about Buffalo Turbine products visit our web site at www.buffaloturbine.com.